Tennessee Abrasive Inc. New Honing Machines and Tooling

Call or email for availability and pricing on all models

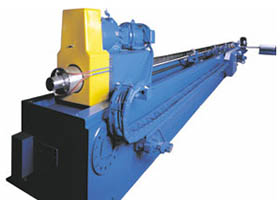

92H-15 Horizontal Honing Equipment

This machine Offers Outstanding Features:

- Self-contained, horizontal honing machine capable of strokes from 8 to 15 foot and bore diameters to 13.5 inches.

- The Spindle Carriage is reciprocated along the way on recirculating roller bearings which provide smooth, friction-free motion under any load. To obtain maximum positive control of the stroke, this assembly is reciprocated by a heavy-duty hydraulic cylinder attached directly to the head.

- Work holding fixtures are adjustable up to 13-1/2". Full contact clamping for minimal distortion of a thin walled work piece.

- To facilitate work handling and provide the operator with an unobstructed view, the centerpiece of the spindle is 46" above the floor.

- LED read-out provided for spindle RPM and stroke speed. DNC program stroke setting. LCD read-out for time.

- Rayon-media coolant filter. This is a self-contained, horizontal honing machine.

- Solenoid-controlled directional valves meet ISO standards. Valves and 15 HP hydraulic pump motor are positioned for easy service.

74H Series Honing Equipment

This machine Offers Outstanding Features:

- The spindle carriage is reciprocated along the way on recirculating roller bearings which provide smooth, friction-free motion under any load. To obtain maximum positive control of the stroke, this assembly is reciprocated by a heavy-duty hydraulic cylinder attached directly to the head.

- Controlled expansion of the abrasives in the tool include a rapid initial-expand feature. The abrasives are expanded at an accelerated rate until they contact the bore surface; at that point, stone expansion is immediately slowed to a pre-determined feed.

- Work-holding fixtures are adjustable up to 20" and wiring is encased in a power track (see above).

- To facilitate work handling and provide the operator with an unobstructed view, the centerpiece of the spindle is 38" above the floor.

- Clockwise or counterclockwise rotation and tool feed pressure are controlled from console. Horsepower load meter and cycle timer are optional.

- Rayon-media coolant filter features automatic advance of filter material.

- Solenoid-controlled directional valves meet ISO standards. Valves and 10 HP hydraulic pump motor are positioned for easy service.

- The head lift is hydraulically adjustable.

- Heat-treated alloy steel tooling with shock resistant tool steel holders is precision made.

75H Series Honing Equipment

This machine Offers Outstanding Features:

- The spindle carriage is reciprocated along the way on recirculating roller bearings which provide smooth, friction-free motion under any load. To obtain maximum positive control of the stroke, this assembly is reciprocated by a heavy-duty hydraulic motor.

- Controlled expansion of the abrasives in the tool include a rapid initial-expand feature. The abrasives are expanded at an accelerated rate until they contact the bore surface; at that point, stone expansion is immediately slowed to a pre-determined feed.

- Work-holding fixtures are adjustable up to 20" and wiring is encased in a power track (see above).

- To facilitate work handling and provide the operator with an unobstructed view, the centerpiece of the spindle is 38" above the floor.

- Clockwise or counterclockwise rotation and tool feed pressure are controlled from console. Horsepower load meter and cycle timer are optional.

- Rayon-media coolant filter features automatic advance of filter material.

- Solenoid-controlled directional valves meet ISO standards. Valves and 15 HP hydraulic pump motor are positioned for easy service.

- The head lift is hydraulically adjustable.

- Heat-treated alloy steel tooling with shock resistant tool steel holders are precision made.

86V Series Honing Equipment

This machine Offers Outstanding Features:

- The spindle carriage is reciprocated along the ways on recirculating roller bearings which provide smooth, friction free motion under any load. To obtain maximum positive control of the stroke, this assembly is reciprocated by a heavy-duty hydraulic cylinder attached directly to the head.

- Controlled expansion of the abrasives in the tool includes a rapid initial-expand feature. The abrasives are expanded at an accelerated rate until they contact the bore surface; at that point, stone expansion in immediately slowed to a pre-determined feed.

- Solenoid-controlled directional valves meet ISO standards.

- 15 HP motor and hydraulic pump are positioned for easy service.

- The 86V has stroke lengths of 24, 48 or 72 inches. Speeds are infinitely variable: spindle 30 to 220 RPM; stroke 40 to 100 FPM; other speed ranges are available.

- Rayon-media coolant filter features automatic advance of filter material.

- LED read-out provided for: spindle RPM, stroking speed, stroke setting.

- LCD read-out for time. DNC program stroke setting.

- Heat treated alloy steel tooling with shock resistant tool steel holders are precision made.

Tooling Equipment

Tennessee Abrasive offers a large array of precision hone tooling. All tooling is machined from wear and shock resistant alloys for durability and a long life span. Sizes range from 1 1/16” to 26” with larger and double length sizes also available. The heads are driven via quick connect involute spline drive or the standard two key drive style of the past. The spline drive offers superior wear resistance in high torque heavy removal applications. With the spline drive changing the tooling is as quick and easy as loosening and tightening a nut. Custom head designs are available to work for any application.

The abrasive holders are machined from tool steel to precision tolerances then heat treated and ground to ensure maximum surface contact with the head to prevent tipping and excessive wear.